As most business owners know quite well, there are two types of fleet vehicle maintenance: unscheduled and scheduled. In order to help ensure that most of your company car maintenance work falls in the latter category, it is important to stay on top of the vehicles and schedule regular preventive check ups.

To make this process as easy as possible, consider the following tips.

Create a List of What Parts and Systems Should Be Checked Regularly

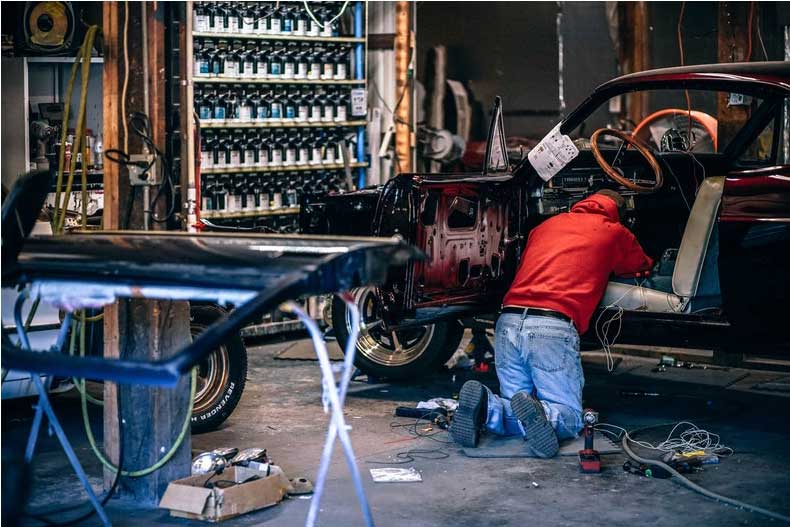

As Verizon Connect notes, a great place to start the fleet maintenance and repair plan is by assessing your specific vehicles and coming up with a checklist of what should be included in the routine preventative maintenance services. These items can include engine oil and filter changes, checks of the cooling and fuel systems, belts and hoses, brakes, horn, fluid leaks, and tires, wheels and rims. To help expedite the maintenance appointments, or if you or your employees have the experience to handle some of these repairs yourself, you may want to keep certain equipment and parts on hand. For instance, stock up on the specific types of oil that each vehicle needs, and consider purchasing a number of o-rings that are found in many parts of your fleet cars, including the braking circuits, the air conditioning systems and the lubricant systems.

Utilize Technology for Your Fleet Maintenance Schedule

Once you know which parts will need to be checked regularly, now it’s time to create a fleet vehicle maintenance schedule. This can be based on a number of factors, including the number of miles that the vehicles have traveled, the number of hours spent on the road and/or a more general “every three months” or other calendar-based method. Keep in mind that each vehicle is different, so you can’t use the same schedule for the entire fleet. For instance, an older truck that has had a few breakdowns within the past year will probably require more regular checkups than a brand-new company van. To help keep tabs on all of the different schedules and track all of the maintenance and repairs, consider using a fleet maintenance software program.

Plan for Unscheduled Maintenance, Too

Even the most well-maintained fleet car will still encounter problems. To be sure that your drivers head out each morning in a safe vehicle, Cerasis suggests that basic things like tire pressure and wheel nuts should be checked and rechecked each morning before anyone leaves — they may discover a nail stuck in the tread or a loose lugnut that would be a safety hazard if the car was out on the road. Drivers should also be taught to listen for odd sounds in the engines and encouraged to report anything that seems amiss. Vehicles that are having tangible issues can be pulled from the schedule and brought in for repair immediately; ideally, another fleet vehicle can be used while the other car or truck is being fixed. By performing daily checkups on the vehicles, you should be able to spot unscheduled repairs well before they become major problems that could take the car out of commission for a long time.

Keep Your Team and Vehicles as Productive as Possible

A fleet vehicle that is sitting idle due to a breakdown is never a good thing. By taking a proactive approach to fleet maintenance and repair, including stocking up on needed parts and using technology to assist in keeping on top of tune-ups, you should have a reliable and well-oiled (pun intended) fleet of cars that will keep your employees and work on schedule.