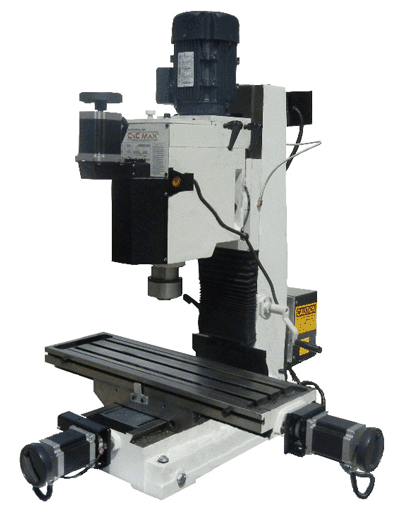

If you are considering to invest in a CNC machine, it is best to be familiar with the things to consider when buying one. Choosing from a CNC machine for sale in the market can be a tough decision. To help you decide, we have listed several features of a CNC machine that you should check.

- Purpose

A CNC machine has different types; each type has various features that may be helpful depending on your intended use of the device. It is best to determine the purpose of the CNC machine for your business before purchasing one. Each type of CNC machine handles different kinds of metals, and their speed varies too.

- Price

Now that you have determined your purpose of buying a CNC machine, the next important thing to consider is the price of the device. Each CNC machine for sale in the market cost varies. The price depends on the features and the size of the device. Make sure to buy a CNC machine that will be helpful for your projects to maximize the full benefits of having one.

- Productivity

Productivity refers to the number of tasks completed in a given time. Productivity is an essential factor to consider since the number of hours spent in completing a job may affect your electricity consumption and machine tolerance.

- Machine tolerance

Always ask your seller about the number of hours the machine can operate. Just like any other machine, there are limitations to how long it can work. If the device has reached the limit of heat it can withstand, it might quickly wear out. Machine tolerance also includes resisting external factors like humidity and cold temperatures.

- CNC machine motor power

The power of the CNC machine motor is also significant because different types of CNC machines require different strengths. Determining your intended purpose for the devices is also helpful in choosing the motor power you need.

- CNC machine size

Buy a CNC machine that will fit an area in your store. Consider buying one that will fit through your door to store it indoors. Sometimes the size of the machine can impact productivity, so buy one that will cater to your needs as a business owner.

- Cooling system

A built-in cooling system is essential, especially if the machine has been turned on for a long time. CNC machines have spindles, and these spindles can produce an excessive amount of heat. A cooling system will prevent overheating that will most likely affect work production.

- After-sales service

Ideally, your seller should be able to help you out with any problems you encounter after your purchase. Repairs and maintenance are the essential services they can offer.

- Transport

CNC machines are not easy to transport. Your seller should be able to provide means to transport your machine safely. If the seller does not have their trucks or vans for transport, ask them for any shipping company affiliations. They might offer discounts or additional services as an affiliate partner. Shipping is the most common way to transport a CNC machine since it is fast and reliable.

Researching the product you want to purchase is great, but it does not always give you the right answers. Always ask an expert machinist about the crucial things in CNC machining. Do not be afraid to ask questions because buying a CNC machine is a significant investment.