Business owners purchase engraving machines to perform specialty services for their customers. More consumers want items personalized and unique, and engraving machines accommodate these requests and give the business more services for their customers. When purchasing a high-quality metal cutting machine, the business must set up training for their workers and ensure that they master all skills needed to operate the machine properly. By reading 10 tips for mastering an engraving machine, the business owner determines what they can get by providing extensive training for their workers.

Learn More About File Format

With laser-cutting machines, the files are vector format and easy to use with the machines. The software design allows the business owner to create files for their projects and upload them to the machine for further use. Once the workers have mastered how to create files and format them properly, they can reuse the designs for projects and improve the way the business operates. They can recreate any design and impress their clients.

Choose the Best Software for Creating Designs

The business owner can connect the engraving machines to a variety of design software, and the designs are transferred to the engraving machine display. When reviewing the design software, the business owner must consider what project types they want to present to their customers.

Use the Correct Materials for the Machine

Each engraving machine has specifications that define what materials are compatible with the tools. Laser cutters can create designs and patterns on wood, steel, and acrylic. Since the laser doesn’t have direct contact with the materials, it will not cause damage, and the business owner gains more versatility in their designs.

Adjust Settings According to the Thickness of the Materials

The thickness of the materials is a major consideration when setting up the projects. The workers must measure the thickness of the materials and enter these details into the laser engraving machine. If they don’t, it will not cut the materials properly and will perform the cut according to the thickness level that appears on the display. This could prevent the material from creating the engraving services appropriately, and the design may go too deep into the material causing issues.

Use the Kerf Correctly

When cutting the kerf is a small number of materials that generate a gap when cutting. It helps manufacturers fit pieces of materials together and achieve the right thickness and diameter. When defining the measurements, the workers subtract half the kerf from the outer section of the material and add half the size of the kerf to the inside portion.

Maintain a Minimum Cutting Distance Between Two Lines on the Material

The worker must measure the distance between two cuts on one piece of material. If they do not distance the cuts enough, the laser cutter will just melt the material together, and it will not turn out as expected. Engraving machines provide specifications about minimum cutting distances, and these details prevent disaster when cutting parallel lines on the material.

Creating Better Details and Patterns on the Materials

An assessment of new details and patterns helps the business owner provide better designs for their clients. By learning how to create better details and patterns, the business owner gains more services to present to the clients, and they can create beautifully crafted engraving for the clients that meet their demands. It’s all in how they create the designs and how well they accommodate the client’s wishes. By collecting new patterns and designs, the business owner can add more details to each order, and they may have an opportunity to provide services that are not available through all engraving companies.

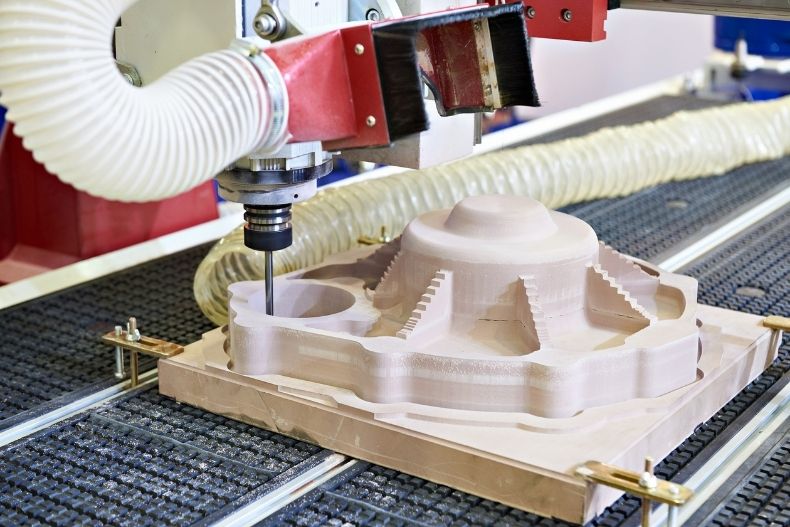

Create Parts for Assembly With Accurate Measurements

Manufacturers create separate parts for their products with laser cutting machines and add the engraving according to the product’s specifications. The workers have mastered the engraving machine and laser cutters when they can perform cuts that line up perfectly and connect well during assembly. Trial and error is a part of the manufacturing processes, and the manufacturer will need to conduct some test runs before perfecting their processes.

They must master all the features to perform the best cuts and set up the projects accurately. By testing the machine and setting up projects correctly, the manufacturer cuts down on recuts and won’t experience higher-than-average material waste. It is a better way to control overhead costs and keep business expenses at a minimum.

Master All Engraving Designs Available With the Machines

Workers need training for the engraving techniques, and the new skills help them to create beautiful patterns and designs for their clients. As they create new engraving designs, they increase their profitability, and workers complete projects at a faster rate while maintaining higher quality work. The business can increase customer satisfaction and increase their services.

When training employees, it is best to teach them how to create all the designs available for the engraving machine first, and the business owner can add to the patterns and designs later. The machine stores all the designs and makes it easier to access them.

Mastering the Art of Creating Text With the Machines

Text is a common request for customers when it comes to engraving. By learning how to create each font on different materials, the workers learn how to complete vital projects for the customers. The business owner needs to ensure their workers master all skills required for operating the machine. This prevents issues for customers and gives them the highest quality of work.

Business owners use engraving machines for creating patterns on products and complete creative tasks for customers. Engraving is a necessary skill for businesses that want to offer personalization services for their clients. The workers must master all skills presented on the engraver to complete complex projects for all customers. These skills can improve the business and keep all the customers happy. By mastering all skills for the machines, the business arms themselves with a fine-tined workforce that can create any patterns or details requested by customers.