The coronavirus has turned the supply chain on its head–in more ways than one. Consumers have quickly adjusted their buying habits as they stay home with friends and family instead of going out to dinner or jetting off on vacation. Businesses that used to sell retail clothes now suddenly find themselves scrambling to stock up on sports and recreation equipment as millions of Americans change their summer plans.

Demand has skyrocketed for online grocery orders, sanitary supplies and other items that aren’t meant for social contact in recent months. Demand has even fluctuated within the food industry. Customers are suddenly ravenous for oat milk, fresh meat alternatives, powdered milk and dried beans, as opposed to produce and thick slabs of meat, which normally rise in popularity during the summer months. Meat plants have been hit hard by the virus and fewer customers are buying fresh meat. Shoppers are also looking for more shelf-stable items as they weather the pandemic. As you can see, there’s a reason for everything.

Improve food and beverage warehouse logistics and learn how to contend with sudden changes in demand so your company can make the best of every situation.

Expect the Unexpected

Preparing for sudden changes in demand means preparing for virtually anything that comes your way. Consumer buying habits can change on a dime, so it’s best to be prepared for both a sudden surge in demand as well as a sudden drop-off. Consider expanding your inventory to include products that some of your customers may use in times of crisis, such as a national disaster, global pandemic or even a terrorist attack.

Life inside your warehouse or manufacturing facility may change as these trends take effect. Create contingency plans so your team knows exactly what to do if the nature of your facility should change. You may need to take additional health and safety precautions, focus on buying and selling new products or change the order fulfillment process to limit the spread of disease. Focus on employee training so you don’t have to start from scratch when adopting these new policies.

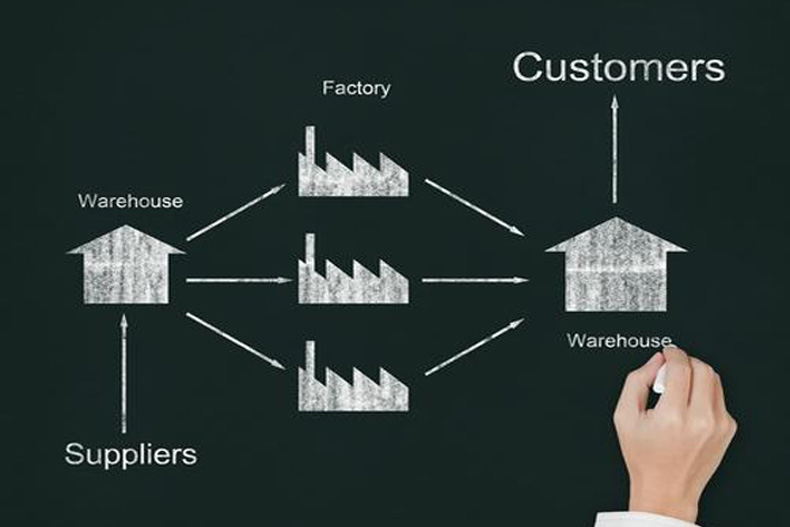

Partner with Additional Suppliers

The coronavirus has changed the way companies source their products. China was devastated by the virus in late 2019 and early 2020, making it nearly impossible for some companies to get the supplies and products they need to keep their customers happy. Industrial production in China fell by 13.5 percent in January and February combined, compared with the previous year.

That’s why you need to branch out and partner with additional suppliers. That way, you aren’t limited to just one company or region. The virus and other global events will affect these areas differently, so it’s best to find suppliers that are close to home, as well as those operating in different parts of the world. Consider reaching out to non-traditional suppliers to see if they are interested in manufacturing new products and taking on new clients.

You need to do this before the crisis hits so you already have these relationships in place when you need them most; otherwise, these companies will likely be flooded with additional requests and orders, which means you’ll have to wait in line.

Don’t Expect Help from the Government

It’s best to take charge when preparing for a crisis instead of relying on outside parties and the federal government. The U.S. response to the coronavirus has been scattershot thus far as each state and county adopts its own safety protocols. The federal government has left the global supply chain to its own devices as private companies battle it out for essential supplies and services.

Stay informed as you adjust to the new normal, but don’t expect a magic solution to your problems. You may apply for federal funding if your facility can no longer function as planned, but it’s best to assume you will have to go it alone in case this help doesn’t come through. You can save up money for additional safety equipment, consider switching to automation to reduce your labor costs and invest in new shipping routes to stay one step ahead of the crisis–and your competitors.

Maintain Employee Health and Safety

Protecting the health and safety of your employees is crucial when resuming production. You should never put individuals at risk just to get your products out the door. Use the latest safety information to create a plan for your facility. Consider the nature of the job at hand so you can reduce person-to-person contact and the spread of disease without reducing efficiency. The coronavirus has made face masks and hand sanitizer nearly ubiquitous in the workplace. Stock up on these supplies to make sure your workers can safely return to work as soon as possible.

Preparing for the worst is about more than just the next pandemic. Do your best to prepare for different kinds of threats, such as the spread of infectious disease, on-the-job accidents and natural disasters that can wreak havoc on your facility.

To improve the safety of your facility during a pandemic, try limiting the number of onsite personnel. Have your workers complete tasks in shifts to reduce in-person contact. You may have to fulfill orders ahead of time, store more inventory overnight in bulk pallet containers or reschedule the delivery timeline. Use bulk wire baskets to move merchandise with fewer employees.

Observe International Trends

Overall, your business needs to stay informed every step of the way in order to fend off future incidents and delays. You should understand the full scope of your business, including your suppliers, workers and customers. Keep track of major storms, novel diseases, cybersecurity trends and public policy changes that may affect your business, including here in the U.S. and abroad. If your business has a facility in another country, keep up with the news to see what’s happening on the ground.

The supply chain is prone to all kinds of sudden changes. Your products may be popular one day and unpopular the next, or vice versa, as your customers adjust their lives to what’s happening in the news. Use this information to keep your business flexible in times of crisis.