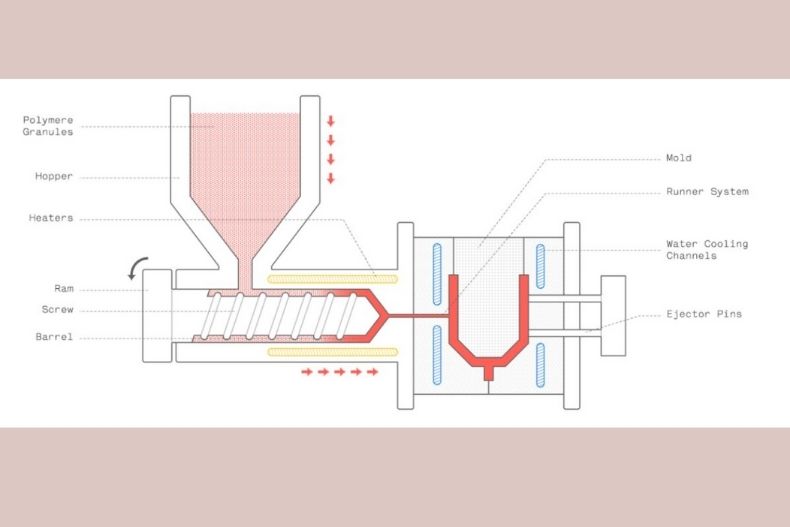

Injection molding is the right manufacturing method for your project if it consists of creating a lot of parts made of plastic. In fact, essentially all plastic products around you at the moment will be created with the help of an injection molding machine. These machines have many different components, while they are available in different configurations as well. This includes a vertical and a horizontal configuration. However, all injection molding machines use an injection unit, a power source, a mold assembly, and a clamping unit in order to perform the four steps of the process cycle. The cost of these machines are quite high, so it is smart to use an injection molding service. Below you can learn more about the injection molding machine, especially about the injection unit and the clamping unit.

The injection unit

The injection unit will do two things: it will heat and inject the material into the mold during the injection molding process. The first component of the injection unit is the hopper. This is a large container into which the raw plastic is poured. The hopper has an open bottom, this allows the material to feed into the barrel. This contains a mechanism for heating and injecting the material into the mold. It often is a reciprocating screw or a ram injector. The material enters the grooves of the screw from the hopper. It is advanced towards the mold as the screw rotates. While it is advanced, the material is melted as well. This is done by pressure, friction, and additional heaters surrounding the reciprocating screw. The molten plastic will then be injected in a quick manner into the mold.

Clamping unit

Before the molten plastic is injected into the mold, the two halves of the mold have to be securely closed. The clamping unit is responsible for this task. When the mold is attached to the machine, both halves are fixed to a large plate. This is called a platen. The mold cavity is mounted to a stationary platen, this aligns with the nozzle of the injection unit. The mold core is mounted to a movable platen, this slides along the tie bars. The clamping motor actuates clamping bars. These push the movable platen towards the stationary platen. Sufficient force will be exerted to keep the mold closed while the material is injected and cooled. The clamping motor will then open the mold so the part can be ejected.